Industrial Heat Exchanger Series

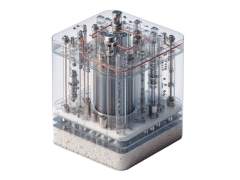

Alfa Laval Mid Europe GmbH- This is Gasketed plate and frame type heat exchanger, with different versions having different working pressure and connections. Please refer datasheet for further information.

- Alfa Laval’s next-generation gasketed plate industrial heat exchangers contain unique features to help your business achieve new levels of efficiency, reliability and serviceability.

- It has better media flow, thermal efficiency and easy service of large units.

Alfa Laval industrial heat exchanger

- Alfa Laval's wide range of industrial gasketed plate heat exchangers is suitable for all types of industry and multiple applications from heating, cooling and heat recovery to condensation and evaporation.

- Our industrial plate heat exchangers are energy efficient, compact, simple to maintain, easy to adjust for capacity changes and represent a relatively low capital investment.

- The vast range of options when it comes to size, plate and gasket material and add-ons means they can be specifically designed and configured for your application, from the simplest of duties to the most demanding where requirements on both performance and documentation are high.

- Our wide range of industrial gasketed plate heat exchangers includes models that are suitable for all types of industries. We can support applications ranging from heating, cooling and heat recovery to condensation and evaporation.

- Alfa Laval’s next-generation T25 and T10 gasketed plate heat exchangers feature a range of unique innovations that break new barriers in industrial heating and cooling applications.

Industrial heat exchanger contruction

- A plate heat exchanger consists of a pack of corrugated metal plates. Each plate is fitted with a rubber gasket, which seals the channel formed between two adjacent plates.

- In an alternative design, every second gasket is replaced by a laser-weld to allow for fluids aggressive to the gaskets. The plate pack is assembled between a fixed frame plate and a movable pressure plate and compressed by tightening bolts.

- The frame plate and the pressure plate are suspended from an upper carrying bar and guided by a lower guiding bar, both of which are fixed to a support column.

- The size of the unit and the material and number of plates are determined by the requirements of the particular application and duty.

- Each individual plate heat exchanger is optimised for its duty and, as a result, the usage of materials is kept to a minimum.

Key features

- Efficiency

- CurveFlow™ distribution area: Improves media flow and minimizes the risk of fouling

- Offset gasket groove: Ensures plate utilization for maximum heat transfer efficiency

- OmegaPort™: Noncircular port holes Enhances media flow and thermal efficiency

- FlexFlow™ plate design: Improves thermal efficiency and optimizes pressure drop utilization

- Reliability

- Five-point alignment: Ensures reliable plate positioning and easy service of large units

- PowerArc™ plate pattern divider: Improves plate rigidity for longer lifetime

- SteerLock™ plate alignment: Ensures reliable plate positioning and easy service

- Serviceability

- ClipGrip™ gasket attachment: Ensures perfect seal and trouble-free maintenance

- Bearing boxes: Guarantees an easy-to-open unit for smoother, more efficient maintenance

- T-bar roller: Provides a lower unit that is easy to service

- Compact frame: Facilitates maintenance and minimizes service area requirement

Benefits

- High energy efficiency

- Flexible – configurable for broad range of applications

- Ensures optimal performance in specific applications based on specific needs

- Easy to install

- High serviceability

Video

Application areas

- Heating

- Cooling

- Heat recovery

- Condensation

- Evaporation

Contact us

- We have the right heat exchanger for you. Fill out the contact us form to contact us today.

| Brand | Alfa Laval |

Alfa Laval is an international Swedish company active in the areas of energy, marine, and food & water, offering its expertise, products, and service to a wide range of industries in some 100 countries. With our broad portfolio of thermal and separation technologies we provide solutions for enabling the transition to green hydrogen. In electrolyser production (PEM, Alkaline, or SOEC), we offer efficient plate heat exchangers for cooling electrolytes, hydrogen and oxygen. Our plate heat exchanger portfolio also includes desalination technologies that allow you to use seawater or river water in your production, which is ideal if you operate an offshore plant. And our heat transfer solutions make it possible to recover and reuse waste heat from the electrolyser to desalinate water, or for other sustainable purposes, such as district heating. We are present in both production and storage, with unique solutions for compression and cooling, as well as innovative printed circuit heat exchangers for refueling stations. Alfa Laval has spent decades developing highly efficient and robust plate heat exchanger technologies. From our fusion bonding technique that enables reliable performance at very high temperatures, to gas-to-liquid solutions that can handle extremely uneven flow requirements, we can offer unique technologies perfect for fuel cell development.