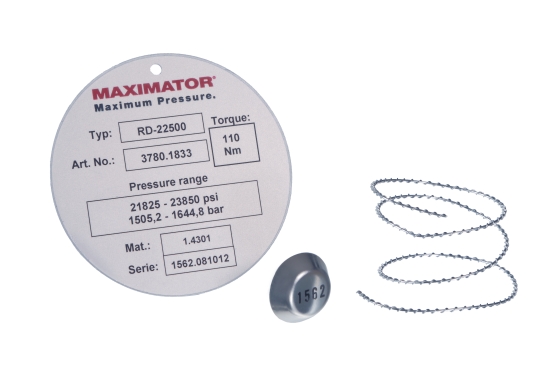

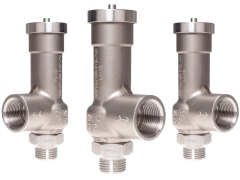

1/4“ Rupture Discs

Maximator GmbH- Rupture disc is a non-reclosing pressure relief safety device that protects a pressure vessel, equipment.

- It is designed to be used with the safety head assemblies.

- Reliable and single material product with pressure range of 67 bar to 1608 bar in different version of the product.

- High pressure relief safety device.

1/4“ Rupture discs

- A rupture disk, alternatively called a pressure safety disc, burst disc, bursting disc, or burst diaphragm, is a non-reclosing pressure relief safety device that protects a pressure vessel, equipment, or system against overpressurization or potentially destructive vacuum situations in most applications.

- 1/4“ angular and flat seat rupture discs are designed to be used with the safety head assemblies.

- Minimum rupture disc pressure ratings should be at least 110% of system operating pressure. The standard material is 1.4404 (SST 316L).

Features

- Material is 1.4404 (SST 316L)

- Rupture Discs are individually packed and marked type plate

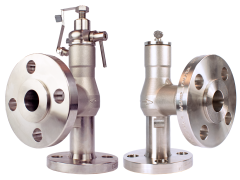

Application

- General hydrogen use

- Medium pressure panels

- Medium pressure fluid handling systems

- Testing application

- As a pressure relief device

Contact us

- Contact us and tell us about your requirements. We will identify the products that provide the performance and safety you expect.

| Brand | Maximator |

| Manufacturing Readiness (MRL) | 10 |

| Technology Readiness (TRL) | 9 |

As an internationally leading company specialized in high-pressure technology, Maximator develops high-performance products and solutions for a variety of uses and applications in the field of high pressure testing and production equipment, hydraulics and pneumatics. Maximator has many years of experience with components, power units and test systems especially for hydrogen applications Many components for the development of this future technology are exposed to extreme stresses. Maximator meets this challenge with innovative high pressure test technology for hydrogen components such as valves, pipes or CGH vessels. We can carry out all legally prescribed testing on pressure bearing components with our test technology: from individual acceptance to type approval testing. We also offer gas control technology for hydrogen applications - approved effective and reliable technology for automotive manufacturers and suppliers.

Latest products