- What is a PEM fuel cell test station, and what are its primary functions?

- Why is it important to test PEM fuel cells, and what parameters are typically measured?

- What components and systems are essential for a fully operational PEM fuel cell test station?

- How do PEM fuel cell test stations simulate real-world operating conditions for fuel cells?

- What safety measures are necessary when operating a PEM fuel cell test station?

- Can you explain the role of sensors and data acquisition systems in a PEM fuel cell test station?

- How do test stations help in optimizing the performance and durability of PEM fuel cells?

- What are the common challenges faced during the testing of PEM fuel cells, and how are they addressed?

- How does the testing process vary for different types of PEM fuel cells (e.g., automotive vs. stationary applications)?

- What advancements in PEM fuel cell test stations have been made in recent years to improve testing accuracy and efficiency?

Browse all fuel cell test station from leading suppliers on our marketplace!

What is a PEM fuel cell test station, and what are its primary functions?

A PEM (Proton Exchange Membrane) fuel cell test station is a sophisticated setup designed to evaluate the performance and durability of PEM fuel cells under controlled conditions. These test stations are essential for both research and development and quality control in fuel cell manufacturing. Also, there is a PEM (Proton Exchange Membrane) is conditioning station which is a specialized setup used to prepare and optimize PEM fuel cells before they are put into regular operation or undergo detailed performance testing. The conditioning process involves running the fuel cell under specific conditions to ensure it reaches its optimal performance and stability. This step is essential for both newly manufactured cells and those that have been stored for some time.

Why is it important to test PEM fuel cells, and what parameters are typically measured?

Generally, PEM fuel cell testing evaluates the performance of cells through the control of fuel (hydrogen, air), humidity, pressure, and temperature. The specific functions are as follows:

- For Performance Testing:

- Voltage-Current (V-I) Characteristics: Measures the relationship between the voltage output and the current draw of the fuel cell.

- Power Output: Evaluates the power output at different loads to determine the fuel cell's efficiency and performance under varying conditions.

- Durability and Lifetime Testing:

- Accelerated Aging: Conducts tests to simulate long-term use and identify potential degradation mechanisms.

- Cyclic Loading: Subjects the fuel cell to repeated start-stop and load change cycles to assess durability.

- Environmental Testing:

- Temperature Control: Evaluates performance across a range of temperatures.

- Humidity Control: Tests the effects of varying humidity levels on the fuel cell's operation.

- Fuel and Oxidant Supply Management:

- Flow Control: Precisely regulates the flow rates of hydrogen (fuel) and oxygen or air (oxidant) to the fuel cell.

- Pressure Control: Maintains and adjusts the pressure of the supplied gases to simulate different operating conditions.

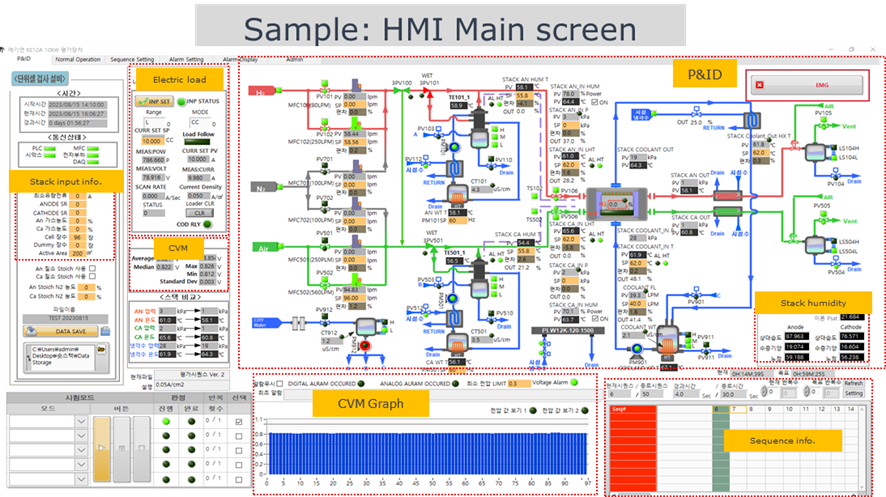

- Data Acquisition and Monitoring:

- Real-time Monitoring: Continuously monitors key parameters such as voltage, current, temperature, and pressure.

- Data Logging: Records data for further analysis and comparison.

- Safety and Protection:

- Leak Detection: Monitors for hydrogen leaks to prevent hazardous conditions.

- Emergency Shutdown: Implements safety protocols to shut down the system in case of critical failures.

What components and systems are essential for a fully operational PEM fuel cell test station?

- Gas Supply System:

- Mass Flow Controllers: Precisely controls the flow rates of gases.

- Humidity Control Unit:

- Humidifiers: Adjusts the humidity level of the supplied gases.

- Temperature Control System:

- Heating/Cooling Units: Maintains the desired temperature of the fuel cell and its environment.

- Thermocouples: Measures temperature at various points.

- Pre-heater: Prevent condensation, enhance performance

- Electrical Load Unit:

- Electronic Load Bank: Simulates different electrical loads to test fuel cell performance.

- Data Acquisition System:

- Sensors and Transducers: Collect data on pressure, temperature, humidity, voltage, and current.

- Data Logger and Computer: Records and processes the collected data for analysis.

- Back pressure regulating module: To control and maintain a consistent pressure of the gases which are used for PEM fuel cell.

How do PEM fuel cell test stations simulate real-world operating conditions for fuel cells?

Precise control over environmental factors such as Temperature, Humidity, Pressure, Dynamic load profiles and gas composition variation.

PEM fuel cell test stations play a critical role in simulating real-world operating conditions by carefully controlling environmental variables, replicating dynamic load profiles, varying gas compositions, integrating with other system components, and testing for long-term durability and safety. This comprehensive testing helps manufacturers and researchers optimize fuel cell designs, ensure reliability, and prepare these systems for actual deployment in various applications.

Examaple: PEM Fuel Cell Test Station Human Machine interface

What safety measures are necessary when operating a PEM fuel cell test station?

- Safety Shut-Down System: If hydrogen or any other relevant gas is detected, the ventilation line must immediately activate, and the test bench must shut down. For any reason, if the control systems (temperature, humidity, pressure, fuel quantity, etc.) fail, the system must safely shut down. Additionally, a shutdown must be initiated in case of abnormal operation of the cell.

- Ventilating System: The ventilation utilities and the test bench's ventilation system are interconnected to ensure that the area is ventilated when any designated gas is detected.

- Hydrogen Supply Line: The hydrogen supply line, including the mass flow controller, valves, pressure switch, and check valves, should be separated from other components. Some manufacturers design and buld their system in such a way that their system isolates these components into a single box to facilitate easy detection of any leaks.

Can you explain the role of sensors and data acquisition systems in a PEM fuel cell test station?

Data Acquisition System connects with each sensor through communication and stores data at intervals specified by the user. The types of sensing are as follows:

- Temperature Sensors: Measure the temperature of the fuel cell stack, individual cells, reactant gases (hydrogen and oxygen), cooling water, and other components. Temperature is critical as it affects the reaction rates and the efficiency of the fuel cell.

- Pressure Sensors: Monitor the pressure of the hydrogen, oxygen, and coolant streams (if needed). Proper pressure regulation ensures the optimal flow of gases and coolant through the system, which is necessary for efficient operation and safety.

- Mass Flow Controller: Operate and measure the flow rates of hydrogen, oxygen (or air), and cooling water. Maintaining the correct flow rates is essential for ensuring the right stoichiometric balance of reactants and for preventing issues like fuel starvation or flooding.

- Humidity Sensors: Monitor the humidity levels of the gases. Proper humidification is necessary to maintain the proton conductivity of the membrane, which is crucial for the fuel cell's performance.

- CVM (Cell Voltage Monitoring) module and load bank: Measure the electrical output of the fuel cell, including the voltage of individual cells and the overall stack, as well as the current output. These measurements are directly related to the power performance of the fuel cell.

- Gas Composition Sensors: Monitor the purity of hydrogen and oxygen, and detect any contaminants that could affect the fuel cell's operation and longevity.

- Conductivity Sensor: A cooling circuit should have certain purity levels to avoid contaminating the fuel cell and affecting its performance.

How do test stations help in optimizing the performance and durability of PEM fuel cells?

The functions of the test station are designed and manufactured to include conditions that simulate both the intended operating conditions and potential fault states. It can conduct various scenarios under controlled conditions, allowing for the evaluation and prediction of fuel cell performance and durability. The test station is designed to meet quality standards that ensure it can handle long-term operation.

- Test stations are crucial for optimizing the Proton Exchange Membrane (PEM) fuel cells. They help identify weaknesses, validate improvements, and ensure that the fuel cells are robust and efficient under real-world conditions.

- Test station allows detailed analysis of how a PEM fuel cell performs under various conditions by checking voltage-current curves, polarization curves, efficiency testing.

- Test station allows durability and longevity testing by providing accelerated stress testing, cyclic loading and start-stop testing, etc.

- PEM fuel cell test stations are indispensable for optimizing both performance and durability. They provide a controlled environment for rigorous testing, allowing researchers and engineers to fine-tune operational parameters, evaluate new materials and designs, and simulate real-world conditions. By identifying and addressing potential issues early, test stations help in the development of more efficient, reliable, and durable fuel cells suitable for commercial.

What are the common challenges faced during the testing of PEM fuel cells, and how are they addressed?

As the performance of PEM fuel cells improves, test stations must also enhance their capabilities to evaluate these advancements.Some manufacturers customizes their test stations to optimally meet the evaluation criteria of its customers. To assess the improved evaluation conditions, the testing equipment is designed starting from a review of the specified requirements. Implementing the required performance within a limited timeframe presents challenges, necessitating extensive design, manufacturing experience, and expertise.

How does the testing process vary for different types of PEM fuel cells (e.g., automotive vs. stationary applications)?

-

Automotive PEM Fuel Cells:

- Dynamic Testing: These fuel cells need to handle rapidly changing loads from acceleration and deceleration. Test stations must simulate these dynamic conditions.

- Start-Stop Cycling: Frequent start-stop cycles, common in urban driving and hybrid vehicles, require rigorous testing to ensure durability.

- Accelerated Aging: To predict lifespan and identify potential failures, accelerated aging tests are essential due to the harsh operational environment.

- Vibration and Shock: Vehicles subject fuel cells to constant vibrations and shocks. Testing must ensure the fuel cells can withstand these conditions.

- Temperature Extremes: Fuel cells must operate reliably in a wide range of temperatures, from cold starts in winter to hot summer conditions.

- Contaminant Resistance: Testing ensures fuel cells can handle exposure to environmental contaminants like dust and pollutants.

-

Stationary PEM Fuel Cells:

- Steady-State Operation: Stationary fuel cells often run at constant loads. Testing focuses on efficiency and stable performance under these steady conditions.

- Long-Term Continuous Operation: These fuel cells are designed for long-term use with minimal maintenance. Testing emphasizes durability over extended periods.

- Thermal Cycling Tests: To ensure reliability in varying environmental temperatures, thermal cycling tests are crucial.

- Ambient Condition Stability: Testing simulates different environmental conditions to ensure consistent performance, whether the system is installed indoors or outdoors.

- Energy Management and Grid Integration: Tests ensure smooth integration with the electrical grid or other energy systems and verify safety and efficiency.

What advancements in PEM fuel cell test stations have been made in recent years to improve testing accuracy and efficiency?

Advancements in PEM fuel cell test stations have led to improvements in accuracy, efficiency, and safety. Enhanced data acquisition, automation, environmental simulation, and safety systems contribute to more reliable and comprehensive testing, ultimately supporting the development of more efficient and durable fuel cells.

Content contributed by

P&P Energytech Co., Ltd. was established in 2004, specializing in the development of fuel cell test stations and diverse BOP test stations. Since our inception, we have proudly held the position of being the leading manufacturer of fuel cell test stations in the market.We provide customized Fuel cell and BOP test stations that meets the testing conditions of each company with our extensive technical know-how in fuel cell testing equipment.If you have any inquiries regarding fuel cell test stations, including PEMFC, PEMEC, SOFC,SOEC, MCFC, PAFC, or other BOP test stations, we would be delighted to offer personalized solutions to meet your specific needs.